Manufacturing enamels from the soil of Greater Paris

NEWS

SEPTEMBER 2022 : EXHIBITION "LIMITED SERIES"

FabBRICK, M.E.G.A, Terres émaillées

3 projects supported by FAIRE*

PROJECT PRESENTATION

The Grand Paris Express suburban railway and the 2024 Olympics will result in increasing construction and therefore more waste. The construction waste from the projects of the Greater Paris could be recovered to create the glazing for ceramic tiles—both inert waste (pieces of ceramic, roof tiles, slate, and glass) and some kinds of non-hazardous waste (metals, slag). Some of them, rich in iron oxides, could be used as pigments, others could serve to replace basic constituents of the glazing.

Another major challenge for the Île-de-France region concerns excavated earth, especially those generated by the Grand Paris Express. They are currently mostly stored away or buried when they could be considered a resource. Excavated earth can be reused to manufacture the pottery tile, or incorporated in the glazing. Different kinds of earth, containing a variety of minerals, will influence the color of the glaze, generating palettes with deep colors that are fully rooted in the Île-de-France region.

The intended outcome would be the manufacturing of enameled ceramic tiles, primarily locally sourced, that tell a story. This would help ease congestion in disposal sites and curb the extraction of the resources required to produce ceramic tiles from virgin materials. Through the presence of ceramic tiles manufactured from rubble, the new building would bear the mark of its past.

SEPTEMBER 2022 : EXHIBITION "LIMITED SERIES"

FabBRICK, M.E.G.A, Terres émaillées

3 projects supported by FAIRE*

Exhibition presented at the Pavillon de l’Arsenal as part of the Paris Design Week and the France Design Week

Free entry from September 8 to 25, 2022

Though design is, by nature, approached through form, contemporary objects are primarily about flows. They tie up, for a time, a certain amount of materials and energy that contribute to their making. Their manufacture involves multiple inputs of production, including materials extracted from mines and deposits, and draws on technical capabilities to duplicate manufactured parts. On a medium and, particularly, a large scale, there are a number of current challenges surrounding production that are highly relevant, including resource depletion, energy use, transport distance, and end-of-life management. Can we still provide the same level of value and pleasure while reducing the impact of production flows? Such is the ambition of the three projects undertaken by Clarisse Merlet, Niveau Zéro Atelier, and Lucie Ponard. Each calls into question the resources, localities, and shaping processes.

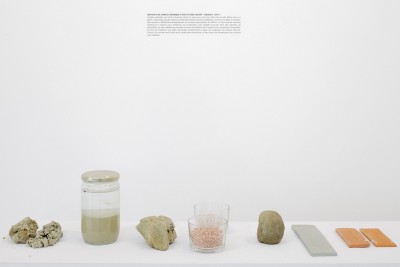

Similar to the few other pioneers reusing the excavated soils of Greater Paris to manufacture construction materials, Lucie Ponard demonstrates the plasticity and the varying hues of the geology of the Île-de-France region. Made from excavated soil from metro lines, limestone quarries, and construction sites that was collected in landfills, the hundred-plus samples and prototypes presented testify to the aesthetic qualities and nuanced palette of the soils of the region. For the French designer, the exhibition forms part of a long-term process that could ultimately result in the batch production of tiles.

Free entry from September 8 to 25, 2022

Though design is, by nature, approached through form, contemporary objects are primarily about flows. They tie up, for a time, a certain amount of materials and energy that contribute to their making. Their manufacture involves multiple inputs of production, including materials extracted from mines and deposits, and draws on technical capabilities to duplicate manufactured parts. On a medium and, particularly, a large scale, there are a number of current challenges surrounding production that are highly relevant, including resource depletion, energy use, transport distance, and end-of-life management. Can we still provide the same level of value and pleasure while reducing the impact of production flows? Such is the ambition of the three projects undertaken by Clarisse Merlet, Niveau Zéro Atelier, and Lucie Ponard. Each calls into question the resources, localities, and shaping processes.

Similar to the few other pioneers reusing the excavated soils of Greater Paris to manufacture construction materials, Lucie Ponard demonstrates the plasticity and the varying hues of the geology of the Île-de-France region. Made from excavated soil from metro lines, limestone quarries, and construction sites that was collected in landfills, the hundred-plus samples and prototypes presented testify to the aesthetic qualities and nuanced palette of the soils of the region. For the French designer, the exhibition forms part of a long-term process that could ultimately result in the batch production of tiles.

PROJECT PRESENTATION

The Grand Paris Express suburban railway and the 2024 Olympics will result in increasing construction and therefore more waste. The construction waste from the projects of the Greater Paris could be recovered to create the glazing for ceramic tiles—both inert waste (pieces of ceramic, roof tiles, slate, and glass) and some kinds of non-hazardous waste (metals, slag). Some of them, rich in iron oxides, could be used as pigments, others could serve to replace basic constituents of the glazing.

Another major challenge for the Île-de-France region concerns excavated earth, especially those generated by the Grand Paris Express. They are currently mostly stored away or buried when they could be considered a resource. Excavated earth can be reused to manufacture the pottery tile, or incorporated in the glazing. Different kinds of earth, containing a variety of minerals, will influence the color of the glaze, generating palettes with deep colors that are fully rooted in the Île-de-France region.

The intended outcome would be the manufacturing of enameled ceramic tiles, primarily locally sourced, that tell a story. This would help ease congestion in disposal sites and curb the extraction of the resources required to produce ceramic tiles from virgin materials. Through the presence of ceramic tiles manufactured from rubble, the new building would bear the mark of its past.

PROJECT TEAM

Lucie Ponard

Lucie Ponard is a product designer and materials designer who graduated from École Duperré and the Royal Academy of Fine Arts The Hague. She works in the field of circular design and eco-design and is fascinated by research around the subject of reuse and recycling. She has worked with various materials including industrial waste and construction scrap.